What is WJP Technology

WJP (White Jet Process) technology is an advanced white ink filling 3D printing technology that employs a sophisticated combination of digital imaging and material deposition techniques to achieve full-color, multi-material, voxel-level 3D printing effects. This cutting-edge technology utilizes high-resolution digital imaging systems to accurately capture the intricate details of the object being printed, while simultaneously depositing specialized white ink materials in precise layers to create a highly detailed and realistic three-dimensional representation of the object.

The WJP technology's ability to produce full-color, multi-material prints at the voxel level allows for unprecedented control over the final product's appearance and functionality. This level of precision enables designers and engineers to create highly customized and optimized solutions for a wide range of applications, from medical devices and prosthetics to educational tools and industrial components.

Moreover, the WJP technology's unique approach to 3D printing opens up new possibilities for material research and development. By leveraging the technology's ability to deposit multiple materials simultaneously, researchers can explore novel combinations of materials and structures, leading to the creation of entirely new classes of materials with unprecedented properties and functionalities.

How Does WJP Works

The basic principle of WJP (White Jet Process) 3D printing technology is similar to inkjet printing technology. After each thin layer of photosensitive resin is printed, it is irradiated with ultraviolet rays of a specific band to polymerize the photosensitive resin material just sprayed onto the molding platform, achieving rapid curing. After each layer is printed, the machine's molding tray accurately reduces the distance by the thickness of the layer, and the nozzle continues to work until the entire part is printed.

Full-Color Printing: Based on the digital color adjustment function of the color management software, various basic color materials can be sprayed through multiple groups of materials through the nozzle, and the materials can be mixed at the same spatial element point to create new materials and color properties, and achieve gradient changes in color and hardness properties.

High-Precision Printing: In terms of precision control, variable ink drop technology and printing compensation ink drop technology have been developed. The printing management software includes innovative variable ink drop technology. By incorporating white ink, transparency, and support materials, the requirements for ink drop thickness, precision, flatness, and color in full-color printing are achieved. Printing Mode: Economy mode 30μm, dedicated mapping mode 21μm, and 600*600*1200dpi printing accuracy.

Efficient Printing: Utilizing a full-width high-speed raster, wide-surface nozzle scanning injection molding method, and the precise design of 3840 sets of piezoelectric nozzles, faster and more accurate printing can be achieved without the need for secondary curing.

Materials for WJP: ABS-like resin

ABS-like resin is a photosensitive resin material specially used for 3D printing, which is designed to simulate the properties of traditional ABS plastics, but is formed through a photocuring process.

ABS-like resin has excellent mechanical properties, including high strength, high rigidity, ability to withstand mechanical stress and load, good impact resistance, and is not easy to break when impacted. It has high printing accuracy and can print high-resolution and fine models. The material also has a certain heat resistance, low shrinkage, and can maintain stability at higher temperatures, reducing the risk of deformation during printing and post-curing. In terms of processing performance, this resin is easy to post-process and can be polished, painted and other subsequent processes.

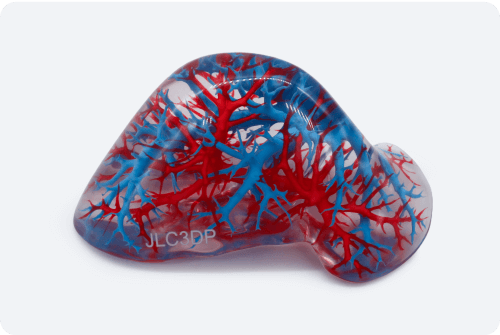

Applications of WJP Technology

Medical 3D Printing

Through WJP color multi-material medical 3D printing technology, hospitals and medical institutions can print 1:1 physical medical 3D models, create patient-specific models on demand, and improve clinical outcomes. 3D printed models have many advantages such as entity, space and touch, which effectively help surgeons optimize preoperative surgical plans and reduce surgical risks.

Cultural Relics Research

In the process of digital modeling of paleontological fossils, there are problems such as local feature loss, low reconstruction accuracy, and poor color reproduction. The Guizhou Normal University team took the Guizhou dragon fossil as the research object, used non-contact laser 3D scanning technology to obtain textured point cloud data, constructed a high-precision, realistic 3D digital model, and used full-color 3D printing technology based on WJP technology to replicate the fossil. The finished model has a smooth surface, fine structure, and high texture and color reproduction. It can overcome the shortcomings of traditional fossil replication methods and ordinary 3D printing technology, and provide technical references for the research, display, and replication of paleontological fossils.

Creative Design

Realistic figure: Make realistic character models to meet collection and display needs and provide

personalized customization services.

Cultural and creative IP: Produce IP derivatives (such as toys, decorations, souvenirs) to achieve the

perfect presentation of complex structures and details.

Art design: Support artistic creation, including art installations, sculptures and models, to enhance the

expressiveness of artworks.

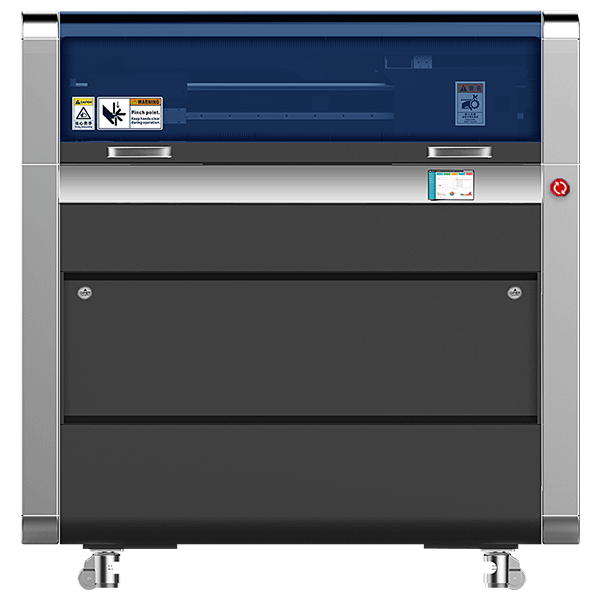

Products Display

Related Articles Recommendation

JLC3DP full-color resin printing service is online! Instructions for placing full-color printing orders WJP Products design guidelines The 5 most recommended full-color 3D printers in 2024 Applying WJP Technology in 3D Printing Realistic Figures